ESCON - HIGH PERFORMANCE CONCRETE

ESCON: (Extra- Strong Synthetic Fiber Reinforced Concrete) is one of the forms of high performance concrete (UHPC: Ultra High Perform Concrete) used as a special construction structure for bridges and pre-stressed concrete structures.

SEEE GROUND ANCHOR

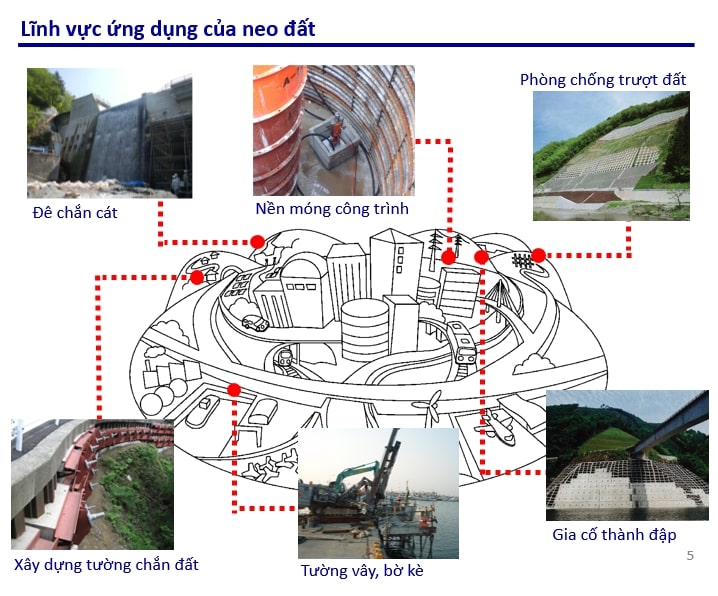

SEEE ground anchors: used in dykes to prevent sand caused by flash floods, building foundations, anti-slippery prevention, retaining walls, reinforcing dam walls, embankment walls, etc.

TIBLE FUNCTION CABLE

TIBLE Function cable: used to reinforce port works, earthquake-resistant reinforcement for high-speed railway, ...

1, ESCON Background

ESCON: (Extra- Strong Synthetic Fiber Reinforced Concrete) is one of the high performance concrete types (UHPC: Ultra High Perform Concrete) which is used as a special construction structure for bridge and pre-stressed concrete structures.

ESCON uses reinforced fibers as synthetic fibers not steel fibers as other UHPC types so that there are many advantages for corrosion resistance when it is used for works in strong corrosion environment.

2, SEEE GROUND ANCHOR

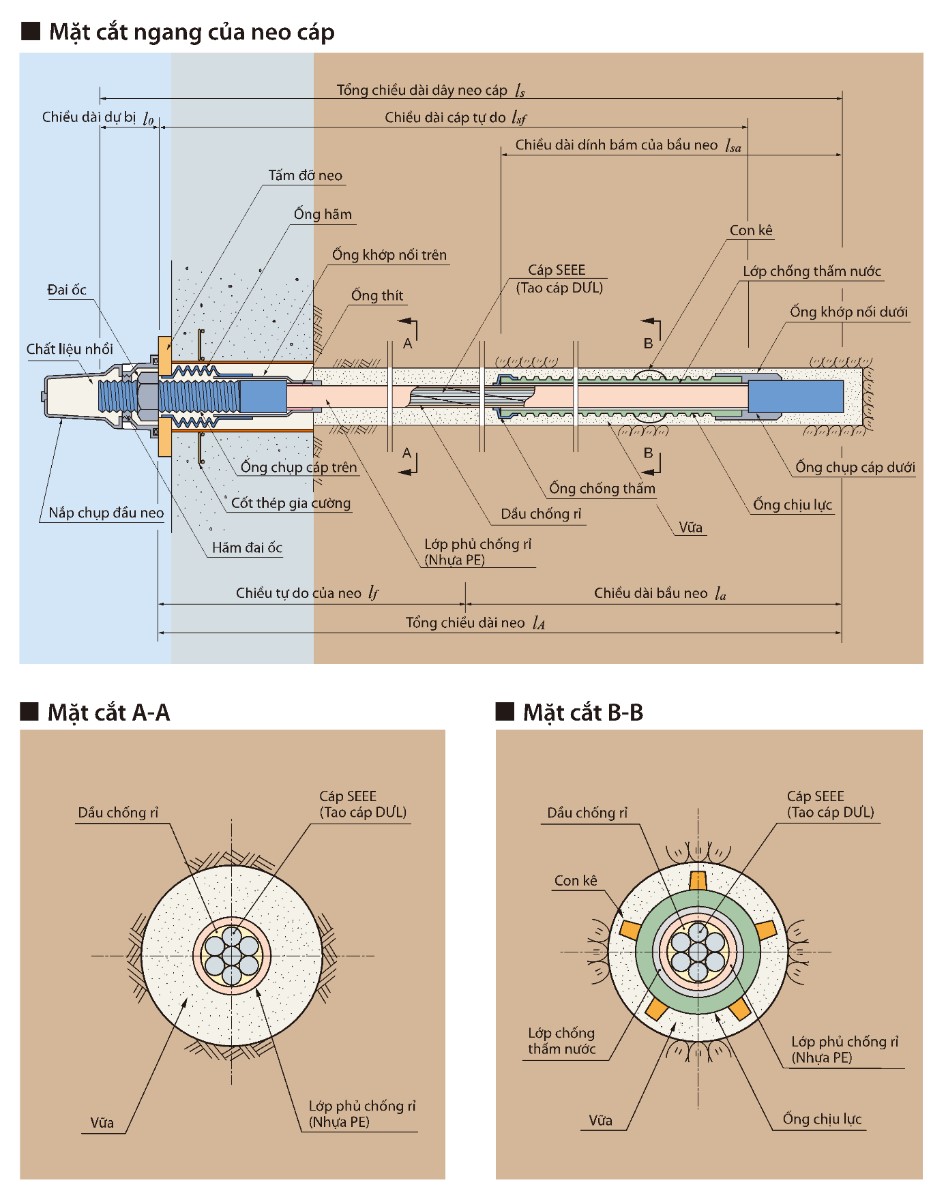

Structure of SEEE ground anchor

1. Double layer anti-corrosion machining: Eternal anchor life

2. Anchor under compression: stable working

3. Fix the anchor head using a nut: easily adjust the anchor tension

3, TIBLE FUNCTION CABLE

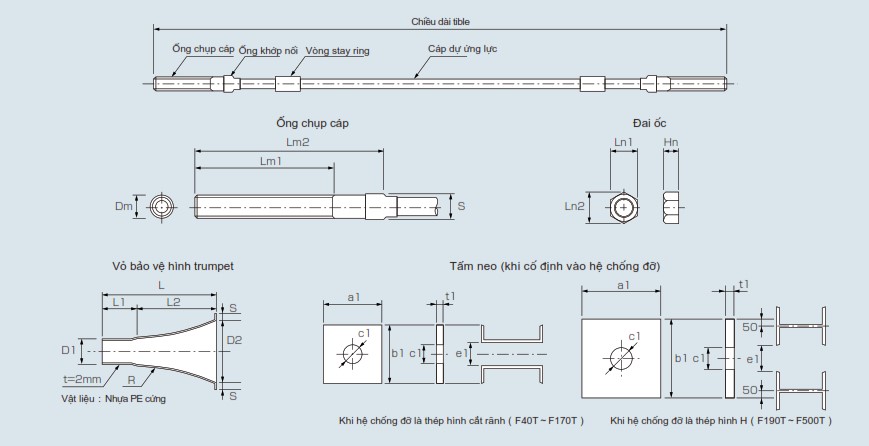

Features of the TIBLE Function Cable

1. Flexibility: The cable uses a twisted prestressed strand from 7 high-strength cables. When used to reinforce steel sheet piles, the effect of bending due to irregular settlement is very small, no washers are required.

2. Uniform quality on the whole cable: The quality of the prestressed strand of the traction cable meets the requirements specified in JIS standards, so the quality is very uniform.

3. Fixed using nuts: The construction is simple and has high reliability. The threaded length of the anchor head always has a spare length, so the ability to adjust when installing is always guaranteed.

4. Perfect Corrosion Resistance: It is a perfect anti-corrosion machined cable through measures such as PE coating the entire cable.

5. Simple construction: The volume of product required to achieve the required tensile force is small (about 1/3 of that of bar steel) so the field work is very easy. No need for screw tensioners, scaffolding.

Cable type F-T: Tible uses prestressed cable (JIS G 3536) has two perfect corrosion-resistant layers: coated with anti-corrosion grease, machined with PE coating. The titble cable is removed when the cable coils are in the state covered with a protective cover, cut according to the design length, and then pressed for plastic deformation of thick steel pipes (called cable tubes) with specialized equipment. to the end of the cable. The cable tube is pressed to plastic deformation so it becomes a unified unit with the cable. The cable sleeve is then conveniently threaded on the outside to create a fixed mechanism using the thread. The waterproofness of the anchor part is guaranteed by the impact of the surrounding pressure, so the PE shielding covers the top part of the cable sleeve. In addition, the end of the cable cradle is covered with a metal cap to ensure complete waterproof.

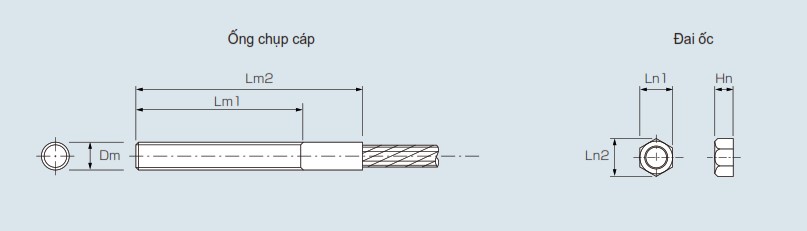

Product structure

Cable type F-K: Cable type F-K is not machined PE coated with corrosion resistance and is intended for use as auxiliary temporary tension cable during construction.

Product structure